Home > Applications > Inspection of Nitinol and Other Metal Tubing

Inspection of Nitinol and Other Metal Tubing

Resources

Triton triple-axis laser micrometers

Ultrasonic wall, concentricity, and eccentricity measurement

Nitinol is an expensive alloy of nickel and titanium (NiTi) with special shape-memory properties. One use of nitinol is in a medical device called a stent. A stent is placed in the body to create or maintain a passage, most commonly for blood (coronary and vascular).

Nitinol is expensive to produce and to process. When the end use is critical, as is the case with stents, manufacturers of stent tubing must inspect it for conformance to wall thickness and either inside or outside diameter specifications.

Contact us to learn more about how our products can help you meet your objectives.

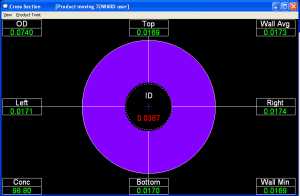

LaserLinc offers a turn-key package for inspecting wall thickness, concentricity, diameter, and inside diameter of cut-to-length metal tubing such as that made from nitinol.

Unique Technology for Wall Thickness and Concentricity Measurement

Due to the unique physical properties of nitinol, non-destructive testing of thin-walled nitinol tubing was previously not commercially viable. However, LaserLinc now offers a high-performance, non-destructive test method based on its UltraGauge+™ ultrasonic material thickness measurement technology. This technology has also been successfully applied to tubing made from other metals and alloys such as stainless steel, cobalt chromium, molybdenum, rhenium, copper, lead, and aluminum.

Diameter and Ovality Measurement

Diameter measurement is performed using one of LaserLinc’s scanning laser micrometers. Generally, a Triton™-series micrometer is used to get the most accurate diameter and ovality checks. When combined with UltraGauge+ wall thickness measurement, the inside diameter of the metal tubing can be calculated.

Highlights

- One system for non-destructive testing of wall thickness, concentricity, diameter, ovality, and inside diameter of thin-wall metal tubing

- Fixture design keeps interior of each tube dry

- Fixture design guarantees proper alignment of the product with ultrasonic and laser gauges, ensuring accurate measurements

- Total Vu™ HMI provides real-time statistics, trending, logging, and reporting, with a surprisingly easy operator interface