Home > Products > Ultrasonic Wall Measurement > Ultrasonic Wall Thickness Measurement Operating Principle

Ultrasonic Wall Thickness Measurement Operating Principle

Ultrasound is a pressure wave with a frequency greater than the upper limit of human hearing (approximately 20 KHz). LaserLinc uses ultrasonic frequencies from 2.25 MHz to 50 MHz.

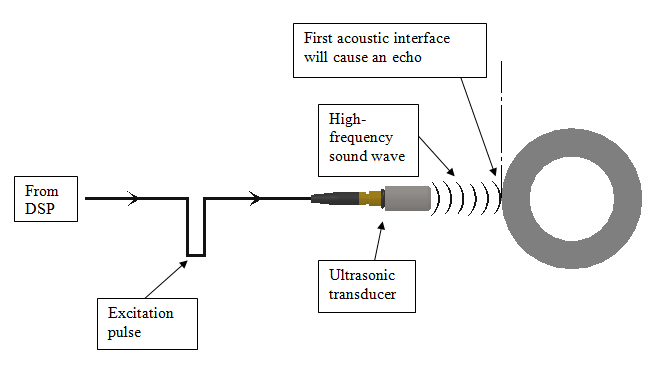

For measuring material thickness, the process involves the following:

- A piezoelectric transducer is excited by a pulse of electrical energy

- The transducer converts the electrical energy into mechanical energy in the form of a sound wave

- The sound wave travels through a medium (water) until it encounters a material with a different acoustic impedance (resistance to displacement by sound)

- At an acoustic interface, some sound energy is reflected—an echo is generated—and some continues onward into the next material

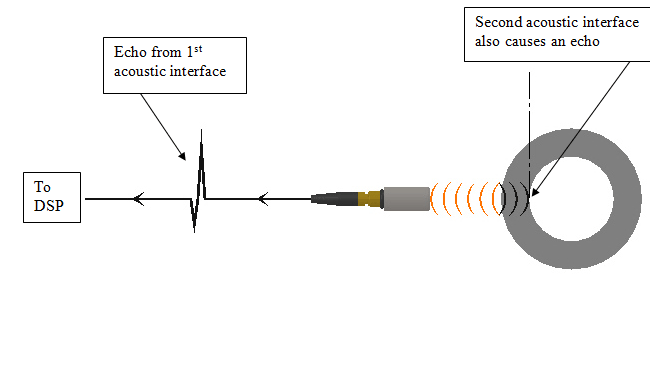

- An echo is generated at each acoustic interface so with a single-layer plastic tube immersed in water, two echoes occur:

- One at the acoustic interface between water and the plastic

- Another at the acoustic interface between plastic and air on the inside of the tube

- Each echo received by the transducer is converted back to electrical energy

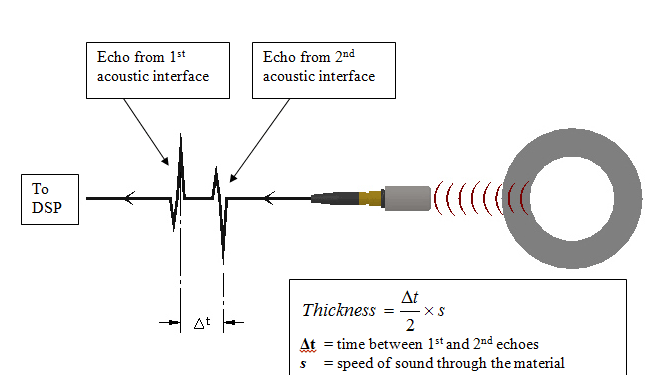

- The electrical signal generated while the transducer is “listening” for echoes is analyzed by a digital signal processor (DSP) to measure the precise time between consecutive echoes

- The time between consecutive echoes is converted to a thickness measurement by multiplying by the speed of sound through the material

The speed of sound through a material is influenced by its temperature. LaserLinc’s UltraGauge+ system provides a feature for calculating the speed of sound through a material, in-process, to automatically account for temperature., and dividing by two (since the sound must travel through the material and back to the transducer)

The speed of sound through a material is influenced by its temperature. LaserLinc’s UltraGauge+ system provides a feature for calculating the speed of sound through a material, in-process, to automatically account for temperature., and dividing by two (since the sound must travel through the material and back to the transducer)