Home > Products > Laser Micrometers > Dual-Axis Scanning Laser Micrometers

Dual-Axis Scanning Laser Micrometers

Dual-Axis Measurement

Resources

Triton™ triple-axis micrometers

Accessories including roller guides, stands, calibration kits, window guards, and air purges

Product safety standards (e.g. CE, UL)

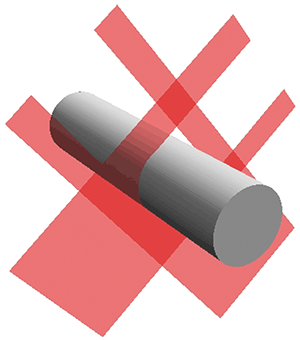

Dual-axis (also called dual-plane) models make measurements from two viewpoints. The two axes of measurement are coplanar and perpendicular to each other. The product to measure is perpendicular to the measurement field. (See the associated image.) Typically, the micrometer is used to measure product diameter, ovality, and position. To see illustrations and explanations of these and other common measurement types available with dual-axis scanning laser micrometers, visit the Measurements page.

For round products, two axes of inspection offer a better average diameter and in many applications, an acceptable measure of ovality, also called roundness or eccentricity

Ovality

Ovality

Eccentricity is sometimes used as a measure of the degree to which two forms share a common center, as in an insulated wire where the core (the wire) and the outer insulation do not share the same center. However, LaserLinc uses these terms to refer to a measure of how well the measured product conforms to a circle. LaserLinc uses the term concentricity as a measure of the degree to which two forms share a common center..

If checking for defects, a dual-plane micrometer can identify defects that do not encircle the product.

Measurement of Rectangular, Triangular, and Hex Profiles

For certain profiles, a dual-axis micrometer offers an efficient way to measure critical dimensions. For rectangular products, one dual-axis device will measure both the width and height (or width and thickness)—proper alignment of one measurement axis with one dimension ensures proper alignment of the other axis for measuring the other dimension. Similarly, with a triangular profile, you can measure the base and height using a dual-axis gauge. With hexagonal products, a dual-axis micrometer can provide an accurate measure of the flat-to-flat distance, regardless of product orientation.

For benchtop applications, a dual-axis model is often sufficient to inspect samples without rotating them.

Dual-Axis Model Overview

The TLAser203™ micrometer is perfectly suited for measuring fine wire, optical fiber, and micro-extrusions with diameters as low as 0.0016 inches [0.04 mm] (even smaller with proper calibration).

The TLAser222™ micrometer is a workhorse with an excellent balance of a wide measurement range. It has a moderate measurement rate, excellent accuracy, in a uniquely compact package that fits just about anywhere. All at an excellent price point. It is well-suited to in-process extrusion applications such as medical tubing, wire, and cable. It is also good for piece-part inspection applications.

For in-process measurement of non-round profiles, products with varying diameter, and flaw detection applications, our remaining dual-axis models can be upgraded to the fastest measurement rates of any scanning laser micrometer: 4,000 Hz per axis (8,000 Hz aggregate). For discrete part measurement, a higher measurement rate facilitates faster inspection cycle times.

Highlights

Dual-axis models share the following characteristics:

- Measure any material, even clear and translucent products (glass logic

Glass Logic

Glass Logic

Glass Logic uses specially designed hardware and software to properly measure objects even when laser light bleeds through them. Without this logic, unexpected bleed-thru would be treated as extra parts or debris in the measurement field and prevent a measurement from being made. This feature is included at no cost with all LaserLinc interfaces. is a software option included at no charge with all systems) - Use in-process or for benchtop/offline applications

- Measurement accuracy and micrometer operation are unaffected by line speed

- Mount in any orientation

- Multiple mounting surfaces with precision locating holes for flexible mounting, but also for flexible attachment of accessories

- Choose from five different models

- Can be used with the Total Vu™ HMI for complete product and process monitoring, reporting, and control

- Can be used with a SmartLinc™ processor for an intelligent interface via industrial communication protocols

- Available with Ethernet-based NetLinc™ signal interface

- Mounting adapters are available to deploy effective four-axis measurement for improved flaw detection and better average diameter

Notable applications include:

- Extruded products such as insulated wire, cable, hose, pipe, and tubing

- Optical fiber

- Corrugated products such as flexible gas pipe, anesthesia or respiratory tubing, and pipe

- Multi-strand measurement of magnet wire, monofilament or other multi-die extrusion

Four-Year Warranty!

The robust design of LaserLinc laser micrometers ensures reliable operation in harsh manufacturing environments. All are covered by an industry-leading FOUR-YEAR warranty that covers all parts and labor. For warranty details, including LaserLinc’s “spare-in-the-air” replacement offer, visit the Warranty and Service page.

These model numbers begin with 2 (the number of axes of measurement), followed by the approximate gate size (in millimeters). The matrix below shows dual-axis models by measurement range and measurement rate.

Click on a model number in the Model column to access its specifications and drawings.

|

Inches |

Metric (mm) |

Measurement Rate (Hz)1 |

||||

|

Model |

Minimum Part Size |

Maximum Part Size |

Minimum Part Size |

Maximum Part Size |

Standard |

Options |

|

.00158 |

.079 |

.04 |

2.0 |

1,200 / 2,400 |

2,400 / 4,800 |

|

|

.003 |

.85 |

.076 |

21.6 |

400 / |

||

|

.007 |

1.15 |

.178 |

29.2 |

1,600 / 3,200 |

4,000 / 8,000 |

|

|

.016 |

2.2 |

.406 |

56 |

1,600 / 3,200 |

4,000 / 8,000 |

|

|

.024 |

4.5 |

.61 |

114 |

1,600 / 3,200 |

4,000 / 8,000 |

|

1Measurement rate is the number of times per second each measurement field (or axis) is scanned. The number after the slash is the aggregate measurement rate for both axes.