Home > About LaserLinc

About LaserLinc

Medical Tubing

Insulated Wire

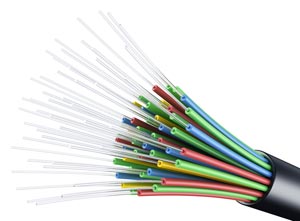

Cable

Hose

Pipe

Optical Fiber

Monofilament

Centerless Grinding

Sample/Part inspection

e.g. automotive shafts

LaserLinc specializes in laser and ultrasonic technology for precision measurement of diameter, ovality (also called roundness or eccentricity)  Ovality

Ovality

Eccentricity is sometimes used as a measure of the degree to which two forms share a common center, as in an insulated wire where the core (the wire) and the outer insulation do not share the same center. However, LaserLinc uses these terms to refer to a measure of how well the measured product conforms to a circle. LaserLinc uses the term concentricity as a measure of the degree to which two forms share a common center., material thickness or wall thickness, concentricity, and inside diameter.

Our technology is applied across a broad range of industries such as medical, automotive, and aerospace. Applications include: wire, cable, hose, tube, pipe, optical fiber, and centerless grinding.

Made In U.S.A.

LaserLinc's products are manufactured in the U.S.A. by American workers. We are a privately held, 100% U.S. owned corporation.

Invest in Your Manufacturing

For a no-cost, no-commitment evaluation of your project, please contact us.

Our focus is on your return on investment (ROI). Our solutions reduce material usage, increase production efficiency, reduce scrap, improve your process, and improve and document product quality. Our service ensures maximum ROI and maximum satisfaction. It is what you expect of a long-term business partner.

| History | |

|---|---|

| 1996 | LaserLinc embarked on a path to serve users of scanning laser micrometers with a direct-to-PC interface. In a world where proprietary, custom “computers” were required, PC interfaces were only available through custom serial communications and analog voltage output. LaserLinc’s TLAser400™ Scanning Laser Micrometer Interface card changed the industry forever, eliminating the need for expensive proprietary processors. The TLAser400 [tee-'lā-zər] card installs on the PC’s motherboard and makes data directly accessible to Windows®-based application software. |

| 1997 | After a number of customized applications for early customers, Total Vu™ software made its debut. |

| 1998 | LaserLinc released its first scanning laser micrometers, the TLAserX22™ family, and introduced them at the WireExpo in Cleveland. The company has exhibited at every WireExpo and InterWire event since. |

| 1998 | LaserLinc moved from its basement origins to a 1,600 sq. ft. building in downtown Yellow Springs, Ohio. |

| 2000 | The TLAser203™ micrometer is introduced for fine wire and optical fiber drawing applications. The gauge is awarded top product of the year designation and appears on the cover of Wire & Cable Technology magazine that year. |

| 2003 | LaserLinc introduced the TLAser260™ micrometer, the first of our high-speed line of gauges for both diameter measurement and flaw detection. At 4,000 Hz per axis, these gauges remain the fastest scanning laser micrometers available. |

| 2006 | The first two models of the Triton™ Triple-Axis family of scanning laser micrometers were delivered. These micrometers deliver a better average diameter. They were the first in the industry to provide an accurate measure of ovality, regardless of product orientation. |

| 2007 | LaserLinc acquired the UltraGage™ product line from Online Controls. The agreement was structured to provide seamless support for existing customers and complete technology transfer. |

| 2007 | LaserLinc moved from Yellow Springs to its current headquarters in Fairborn, Ohio, a 20,000 sq. ft. facility. While at the time it seemed excessive, operations now utilize almost all of the space! |

| 2008 | LaserLinc introduced the UltraGauge+™ product line for wall thickness/material thickness and concentricity measurement. |

| 2013 | The SmartLinc™ processor with industrial fieldbus/Ethernet communications (e.g. EtherNet/IP) for LaserLinc’s full line of scanning laser micrometers was released. |

| 2013 | The Ethernet-based NetLinc™ interface for scanning laser micrometers is released. A standard Ethernet connection means just about any Windows®-compatible PC hardware platform with an Ethernet connection can be used with LaserLinc’s micrometers. |

| 2014 | The TLAser103™ and TLAser1240™ models broaden the measurement range of LaserLinc’s line of scanning laser micrometers to as small as 15μm [.0006 inches] and as large as 228.6mm [9.0 inches] |

| 2016 | LaserLinc releases version 6 of its flagship Total Vu HMI platform for process and product monitoring and control. Highlights:

|

Microsoft, Excel and Windows are either registered trademarks or trademarks

of Microsoft Corporation in the United States and/or other countries.

OPC is a registered trademark of the OPC Foundation