Home > Products > Product and Process Monitoring > Total Vu™ HMI > Open Productivity and Connectivity (OPC) Client & Server Software

Total Vu™ HMI - Open Productivity and Connectivity (OPC) Client & Server Software

Total Vu™ Capabilities

Reports using Excel ® templates

Max/Min for irregular and non-round profile measurement

Open Productivity and Connectivity (OPC®) software

Fast Fourier Transforms (FFT) and Structural Return Loss (SRL)

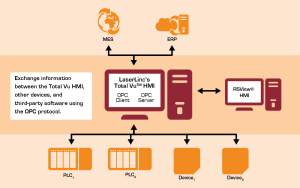

LaserLinc understands that our products must work in a diverse manufacturing environment. Today, information flows from the front-office down to the manufacturing floor, and vice-versa. Information also must be shared amongst devices and software applications on the same production line. OPC is one of the most powerful and flexible ways to meet this need.

The OPC module for Total Vu software makes Total Vu configuration settings, status, and measurement data accessible to other devices and applications. OPC allows other systems to trigger or automate virtually any action within the Total Vu HMI.

OPC UA

With the introduction of the Universal Architecture (UA), OPC is now a universal protocol. Data can now be exchanged directly between PCs, PLCs and other devices with OPC UA--no gateways or bridges are needed, provided the receiving device is a client.

The importance of Server and Client functions

Most devices only offer Server functions. A server listens and waits for requests before responding. If two devices need to exchange information, and both are OPC Servers, then 3rd party software is required: an OPC Bridge which will act as a client to both servers.

An OPC Bridge to direct traffic between two servers adds cost, complexity, and another software tool to learn and maintain.

Since the Total Vu platform acts as both an OPC Client and an OPC Server, information can be easily acquired from or sent to other OPC-compliant platforms for a fully integrated and connected plant floor.

Some Special Uses

OPC is one of the many ways in which a Total Vu system can gather process data and product measurement characteristics as part of building an audit trail.

OPC is a software-only option for implementing the closed-loop feedback control function. In this configuration, the Total Vu HMI determines the optimal setting for the controlled parameter, such as line speed or extruder RPM, and shares the setting with the PLC or other device that maintains the speed or RPM. No other hardware is required with this method.

To learn more about the OPC standard, visit the OPC Foundation website: opcfoundation.org.

Microsoft, Excel, and Windows are either registered trademarks or trademarks

of Microsoft Corporation in the United States and/or other countries.

OPC is a registered trademark of the OPC Foundation